Freephone: 0800 072 1110

Telephone: 0117 982 1064

Portview Road, Avonmouth, Bristol BS11 9LD

Portview Road, Avonmouth, Bristol BS11 9LD

The cylinder block comprises the main body of the engine. Due to the constant, reciprocating action of the pistons the cylinder bores can become worn over time. Piston and bore damage can also occur if the engine has been excessively over-heated or poor atomisation of fuel.

If damage or wear has been caused to your cylinders we can rebore your engine and supply oversize pistons (assuming availability). Even if the bores have been damaged beyond the maximum oversize there is the possibility of boring and fitting a cylinder liner to bring the cylinder bore back to standard size. After a cylinder is bored it will then be honed to polish the slightly rough finish.

All new engines are supplied with standard pistons, after reboring the diameter of the cylinders will increase, which will require oversize pistons to be fitted. These can be available in a range of sizes and we can enquire as to what sizes are available before boring. If oversize pistons are not available we can fit a cylinder liner which will bring the cylinder back to the standard size.

Some new engines are supplied with liners already fitted to the engine block, if these become damaged or worn we can remove them using our hydraulic pulling equipment, once removed we can then go on to fit new liners.

This work is carried out by high precision machinery by a team of engineers with over 50 years of experience.

If a cylinder bore is minutely damaged it could possibly be honed rather than bored. With this process what we are trying to achieve is to remove any damage to the cylinder bore without the need to substantially alter the bore diameter which will require the need to fit oversize pistons. If we can achieve this than as long as the piston is not damaged in any way it may be re-fitted with new piston rings.

After reboring we would then carry on to hone the cylinder. With honing what we want to achieve is a cross-hatch pattern finish which retains a layer of oil to aid lubrication when running in.

After boring/honing we would highly recommend the use of a specifically made running in oil for the first 1000 miles after the engine has been rebuilt. This is used to bed the new pistons/rings into the bored/honed cylinders. This is to prevent the bore from glazing, which could lead to smoking problems.

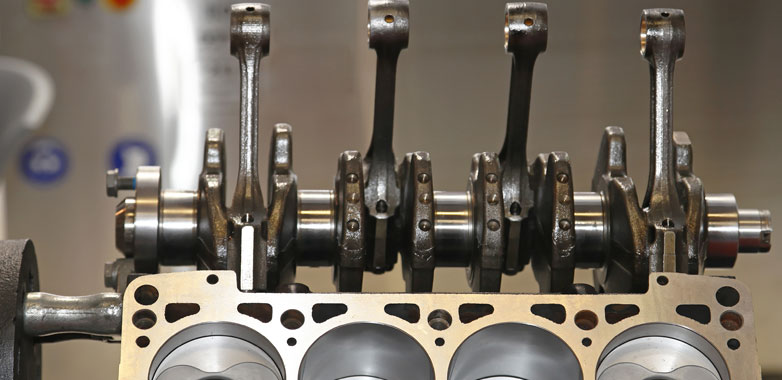

The crankshaft is the part of the engine that translates reciprocating liner piston motion into rotation. The crankshaft and crankshaft bearings can become damaged if they are not lubricated correctly, I.E, loss of oil or poor oil pressure. This can cause a knocking noise and could lead to a massive failure of the engine.

All new engines are supplied with a standard crankshaft and bearings. If the crankshaft journals have become damaged or worn we are able to grind the crankshaft. This would involve us removing material from the crankshaft journals to eliminate any damage or wear it may have. As we are removing material from the crankshaft the diameter of the journals will be reduced so undersize bearings will need to be fitted. These bearings can be available in a range of sizes and we can enquire about the availability before grinding the crankshaft. After the crankshaft has been ground we then polish it to provide the perfect finish.

If a crankshaft has been minutely damaged or worn and is still within tolerance we should be able to polish the journals rather than grind them. Doing this prevents the need to fit different size bearings, I.E., if the crankshaft is standard size you would be able to fit new standard bearings.

As well as grinding and polishing crankshafts we also offer crankshaft testing services. We electromagnetically test crankshafts using a ultra-violet fluid to detect any cracks in the crankshaft. If the crankshaft passes this test we can then set up the crankshaft and check the alignment to confirm the crankshaft has not been bent.

If an engine suffers a crankshaft failure the main bearings can become seized onto the crankshaft and can spin in the bearing housings which will damage the main bearing housing, I.E, the block itself and the main bearing cap.

If this happens we are able to line bore the main bearing housings, this will remove any damage which has been caused. However this will also increase the diameter of the main bearing housing resulting in the need to fit oversize housing bearings. Unfortunately not many vehicle manufacturers list oversize housing bearings.

If this is the case we will need to look into ways to reduce the main bearing housing diameter. These could include manufacturing and fitting sleeves. Alternatively we could machine the main bearing cap and block mating surfaces which would reduce the main bearing housing diameter which can then be bored to the standard size.

The con-rod (connecting rod) is what connects the piston to the crankshaft. This forms a simple mechanism which translates reciprocating motion into rotation motion and vice-versa. If you believe you have a distorted con-rod we are able to check its alignment and advise if it is indeed distorted. If the con-rod has become distorted we may be able to re-size it and bring it back to its original specifications. This depends on what type of rod you have, i.e. if it is a cracked rod we are unable to resize it. Re-sizing is also dependent on how badly distorted the con-rod is.

To resize a con-rod we have to machine the con-rod and the cap mating surfaces and then the big end bearing housing is honed back to the original specifications.

In the majority of con-rods there is a bush fitted in the small end which the piston gudgeon pin fits through, over time or due to a lack of lubrication this bush can become damaged or worn. Rather than having to replace the con-rod we are able to remove this bush and fit a new which is then honed to size. If a new small end bush is not available for your vehicle we are able to manufacture them using our in-house machining services.

If a con-rod does not have a small end bush it is likely that the gudgeon will need to be press fitted into the con-rod, we are able to offer this service for a minimal cost.

The flywheel is a key part of the transmission of your vehicle transferring energy from the engine into the transmission via the clutch. Over time your flywheel can become damaged or worn, if this happens we are able to resurface your flywheel creating a perfect surface for your clutch to engage with. Unfortunately we are unable to resurface dual mass flywheels if your vehicle runs a dual mass flywheel and it has a problem it will need to be replaced.

Metal stitching, has become a generic phrase that describes methods of repairing cracks in cast metals without welding. Why metal stitching? Well, primarily because of the need for an alternative to the difficulties encountered in welding. Cast iron is the most difficult of all common cast metals to weld. All electric welding methods for cast iron have proven to be less than satisfactory and in many cases can cause even more cracks.

Many different concepts have been tried over the years and most have been called metal stitch. A main part of the process that replaces the crack itself is the stitching pins. Some of the items that have been and are still used are: bolts (copper-and zinc-plated); tapered plugs (both threaded and non-threaded); threaded rods; screws; set screws; dowels; and just about anything else that could be stuffed, hammered or screwed into the space. Over time, these items have been called 'plugs', 'pins' and 'stitching pins'.

There are currently two styles and multiple thread lengths and diameters available. The other element of metal stitching is the locks. They are primarily used in industrial repairs although there are applications in smaller castings. Locks require a flat spot for installation. Locks have also evolved over the years and have been created in many shapes, sizes and strengths.

Many repairs may require using only stitching pins such as in cracked cylinder head repairs and cracked engine block repairs. Often large industrial repairs with structural damage only that don't require sealing the crack can be repaired with Locks only.

A comprehensive range of engine testing & repairing services are available for all makes and models.

Price Bros. also carry large stocks of new engine components.

We offer certain services on-site, please see link at top of page for details.